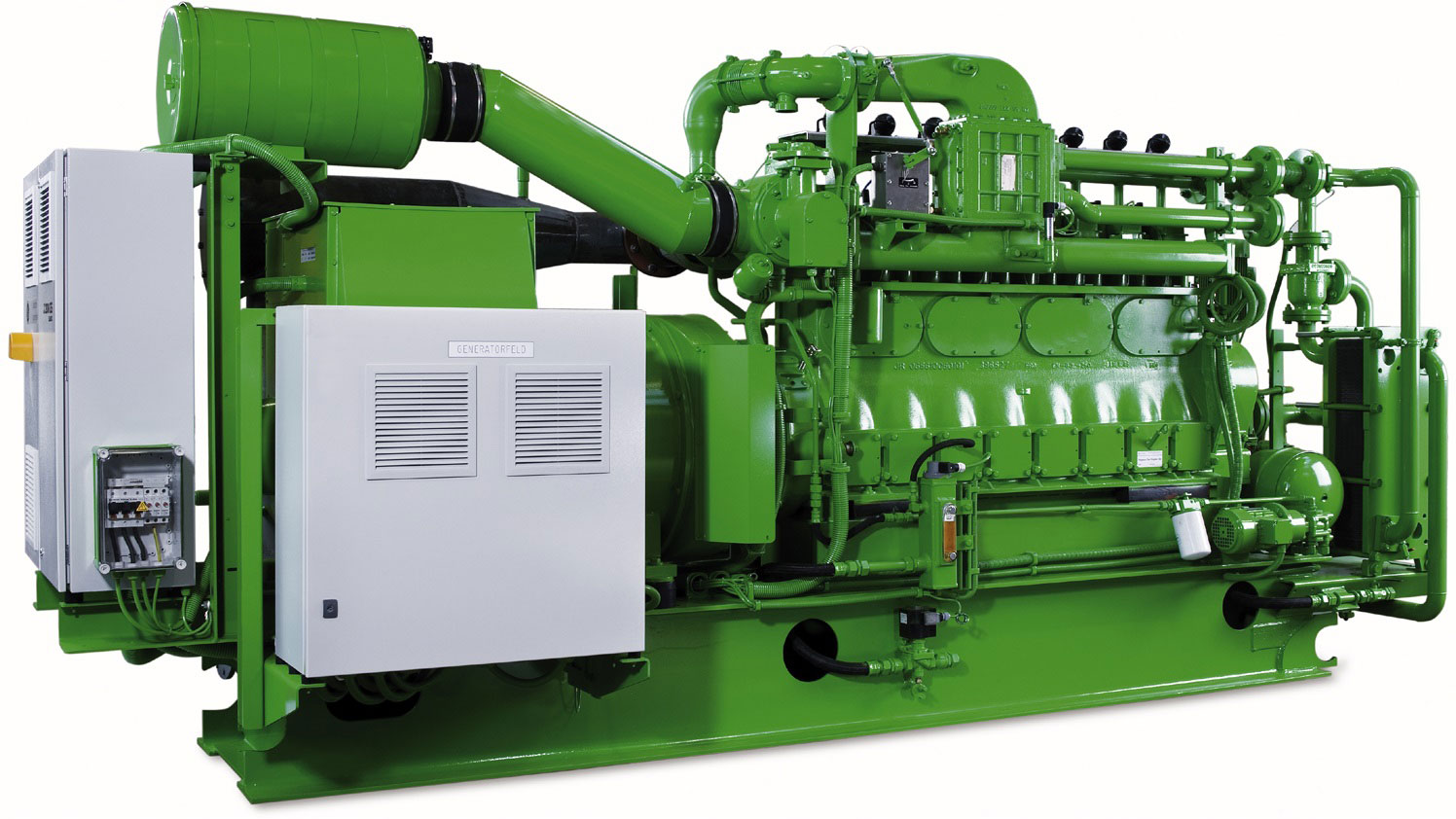

Cogeneration and turbocompressor

Cogeneration is an ever-expanding sector in Italy; engines can work at full speed for up to 24 hours a day 365 days a year producing electricity and heat.

It is exactly for this reason that LMTD developed a plan that allows the standard overhauling of a turbocharger with a timing that varies from 5 working days, up to just one day in urgent cases. To make this possible we have developed a careful plan of the work in the workshop and a constant restocking of spare parts in our warehouse.

The planning described is aimed at the optimisation and rationalisation of the main turbochargers such as KBB HPR3000 – KBB HPR4000 – PBS NR17/SJ – PBS NR20/SJ – PBS TCR12 – PBS TCR14 – PBS TCR16 – ABB RR131/14 – ABB RR151/14 – ABB TPS48 – ABB TPS52 – ABB TPS57 – ABB TPS61

The aim of our cogeneration policy is to allow the workers to minimize the machine downtime.

Electro-fans

With the intention to satisfy the continuous market’s demands and to guarantee and strengthen our relationships with customers, our Company, since some years, in addition to turbo chargers core business, is also able to assist you in the field of special electro-fans overhaul or sales activities in compliance with ATEX standards and rules.

This service is offered mainly for the following brands:

- Meidinger

- Mapro

- Savio

- Continental

For this purpose we set up a special department provided with all equipments and instruments necessary to verify and carry out the following:

- Ultrasonic cleaning;

- Electrical motors insulation;

- Belts tensioning;

- Electronic alignment of pulleys and couplings;

- Impellers balancing;

- Pressure tests

- operational tests of complete fans/motors after overhaul.

Our staff has been trained according to ATEX regulations.